Home Technology Ev and concept cars Tesla’s Great Experiment: Tu...

Ev And Concept Cars

CIO Bulletin

01 October, 2024

Introduction

Walk into any Tesla Gigafactory and you’ll see a place that looks like the future. Giant robots glide along assembly lines. Batteries are stacked in towering arrays. Sparks fly as aluminum chassis come together.

Yet, for all the technological theater, much of what makes these factories tick still relies on the same principles that have defined manufacturing for a century: plan, produce, inspect, ship.

Today, Tesla is betting that model is due for a complete overhaul. Their vision is to build not just a factory but a living organism - a self-learning, predictive, and responsive system where every machine, shipment, and customer touchpoint feeds a common brain.

This is the story of how Tesla plans to do it - and why it matters.

How We Got Here: A Short History of Tesla Manufacturing

When Tesla launched the first Roadster in 2008, it was an underdog with a rented corner of a factory. Production was slow, often improvisational.

By the time the Model S arrived, Tesla had outgrown startup scrappiness and moved into a former GM-Toyota plant in Fremont, California. The Model 3 era brought further evolution:

Each of these facilities advanced Tesla’s process maturity. But they also introduced complexity:

Tesla needed a way to unify all of this—without slowing down.

The Limitations of the Coordination Model

Until now, Tesla’s factories operated under what’s called a Coordination Operating Model.

This approach wasn’t inefficient by historical standards - but it wasn’t resilient either.

During the COVID-19 pandemic, Tesla saw first-hand how brittle global supply chains can be. A single delayed component could ripple through production for weeks.

That experience became a catalyst for change.

Illustration: Moving from Coordination to Unification.

The Unification Model: A New Blueprint

The heart of Tesla’s transformation is the shift to a Unification Operating Model.

Instead of relying on slow consensus and manual handoffs, this model uses AI and IoT to create:

This vision requires weaving together several layers of technology:

Let’s break down how these elements work.

AI Forecasting: Seeing Demand Before It Arrives

Traditionally, Tesla used regression models to forecast sales - analyzing past orders and trends.

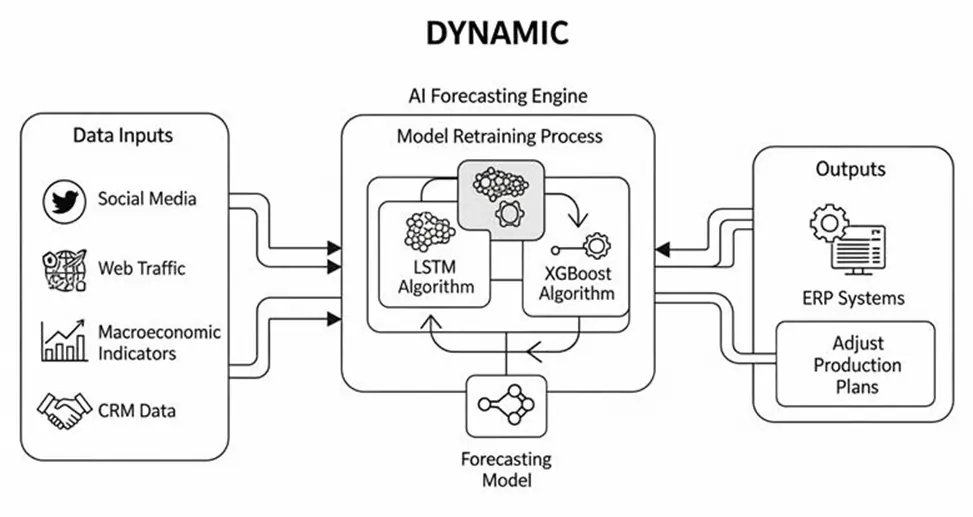

The next generation of forecasting is more dynamic:

This means if Model 3 orders spike after a new subsidy announcement, the system can start reallocating resources the same week.

AI Risk Simulations: Stress-Testing the Supply Chain

Supply chains break in unexpected ways - weather, politics, factory accidents.

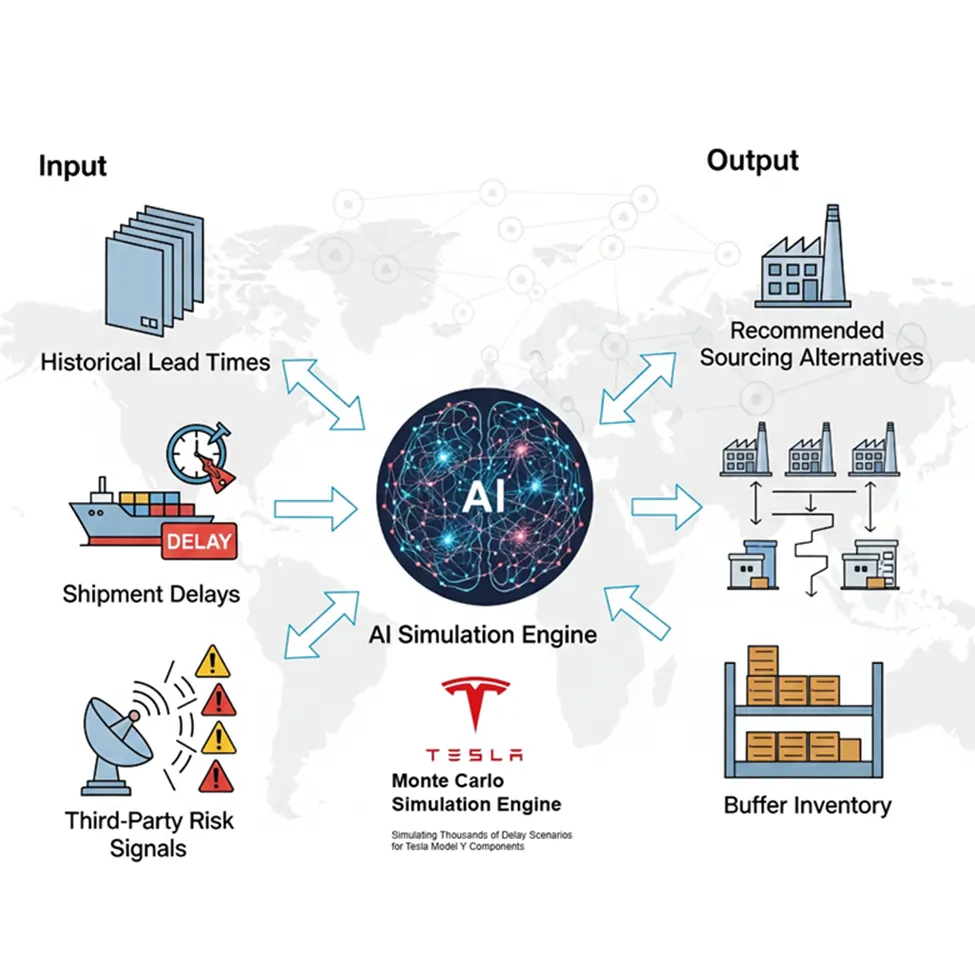

To anticipate these risks, Tesla runs Monte Carlo simulations across supplier data.

Here’s how it works:

This moves supply chain management from reactive firefighting to proactive scenario planning.

Example: AI simulating supplier delay scenarios.

IoT and Digital Twins: Building a Mirror of the Factory

If forecasting is the brain, IoT is the nervous system.

Tesla’s factories now deploy:

For example:

Before a new battery configuration goes into production, the digital twin runs it through stress tests, checking for quality issues.

If anomalies are predicted, the real factory can adjust calibration automatically.

Closing the Loop: Learning From Every Car

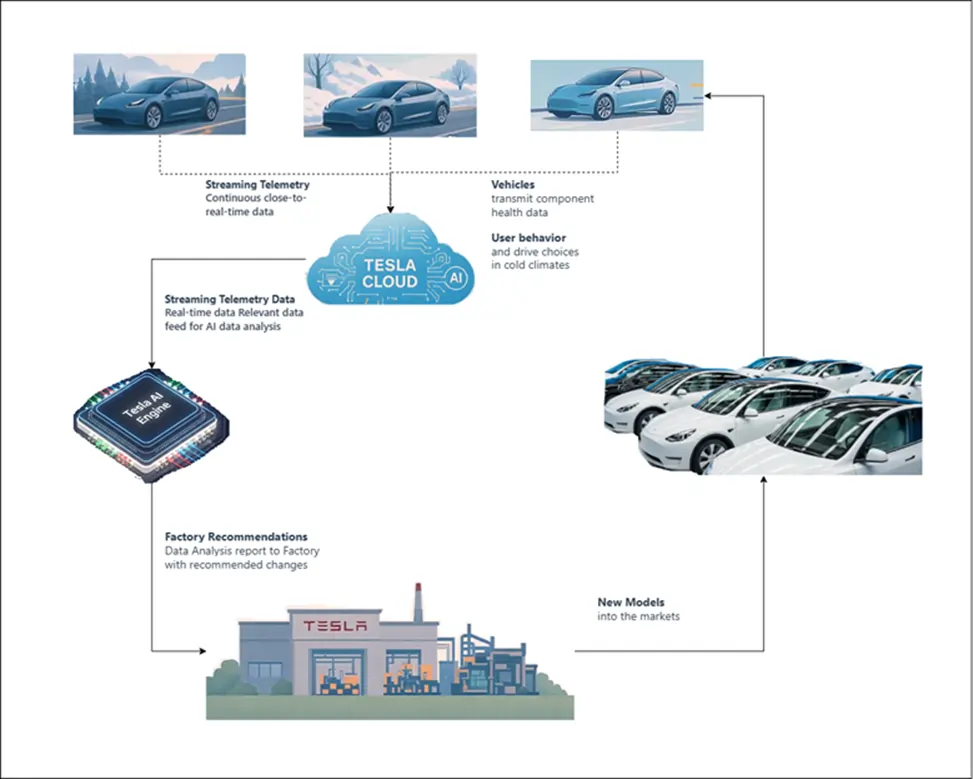

A Tesla vehicle doesn’t stop generating data when it leaves the factory.

Every Model Y in the field:

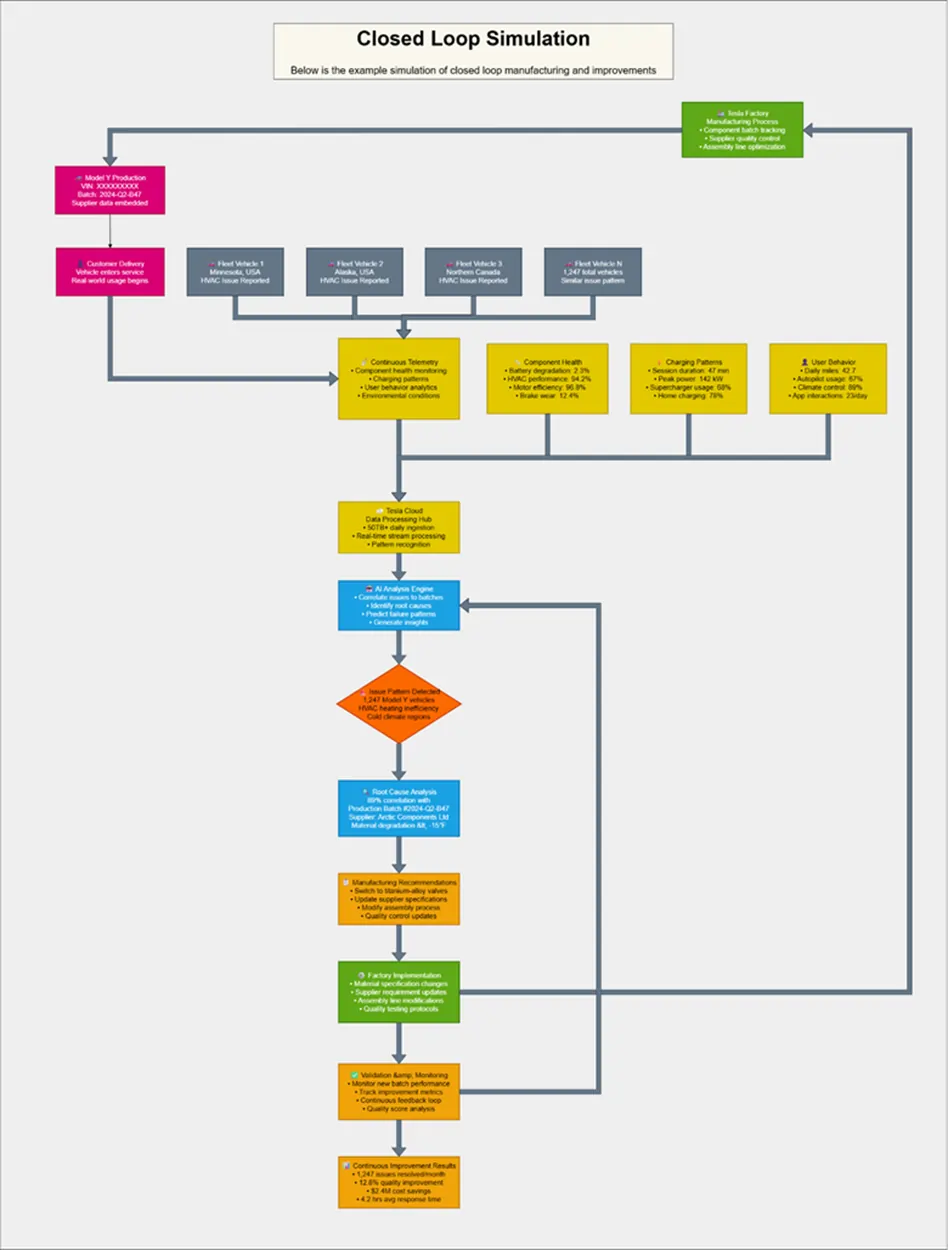

If thousands of vehicles report HVAC issues in cold climates, the AI correlates

those incidents to a specific batch or supplier.

The system then suggests changes in materials or assembly techniques - creating a continuous improvement cycle.

Illustration: How delivery data flows back into manufacturing.

Managing the Risks of Generative AI

Tesla doesn’t only use machine learning for predictions. It also leverages Generative AI (GenAI) to create simulations and summarize support tickets.

But GenAI can hallucinate - producing plausible but incorrect information.

To prevent this, Tesla applies a three-layer defense [(Ji, 2023)]:

These safeguards reduce error rates by over 90% [(Amodei, 2016)].

Why It Matters: The New Playbook for Manufacturing

Tesla’s ambition goes beyond improving its own margins.

If successful, this transformation could:

In an era of constant disruption - from pandemics to geopolitical shocks - Tesla’s approach could become the default, not the exception.

Conclusion

What Tesla is attempting is, in many ways, the logical endpoint of its philosophy: software eating hardware, intelligence embedded everywhere, and constant iteration.

If it works, the Gigafactory won’t just be a place where cars are made. It will be a living system—one that senses, learns, and evolves faster than any competitor.

And if it fails? Well, it won’t be for lack of trying.

About the author:

Sharathkumar Chandrasehkar is a Solution Architect and Senior PLM Consultant with over 18 years of IT experience, including extensive expertise in FlexPLM implementation, upgrades, integrations, and complex customizations across the Retail, Apparel, Footwear, and Consumer Goods sectors. He has delivered high-impact digital transformation initiatives using VibeIQ for leading global brands, focusing on system modernization, data migration, 3D product experiences, and cloud-native architectures.

Sharath holds a Master of Science in Computer Information Systems with a specialization in Project Management from Boston University, where his studies explored enterprise architecture, cloud integration, agile methodologies, IoT applications, and data-driven decision-making. His academic work combined practical problem-solving with emerging technologies, reinforcing his ability to bridge business needs with innovative technical solutions.

Sharath’s work combines deep industry expertise with hands-on technical execution, ensuring that complex IT solutions not only meet technical requirements but also align with strategic business objectives.

Insurance and capital markets