Home Technology Aviation How CNC Machining Handles Comp...

Aviation

CIO Bulletin

23 April, 2025

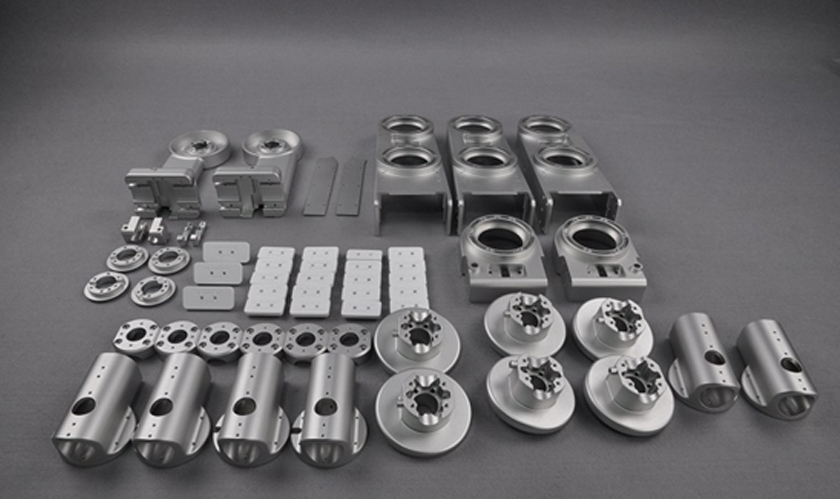

CNC machining has become a cornerstone in producing precision components for aerospace and medical industries where complex geometries and tight tolerances are non-negotiable. The unique combination of precise design handling and accuracy enables CNC machining services to manufacture essential components like turbine blades, orthopedic implants, and surgical instruments. This exploration examines CNC machining approaches to managing complex forms within high-demand industries while covering contemporary technologies and substance analysis along with production improvement methods.

Aerospace and medical components contain intricate forms, including curved surfaces, which demand both high precision and dependable product manufacturing. The combination of computer-controlled technological equipment used in a CNC machining service assures that every manufactured part aligns with detailed industry requirements. Combining multi-axis machining alongside advanced tooling and detailed process planning through CNC machining enables high precision and quality requirements for these essential applications.

CNC machining services' primary method of handling complex geometries depends on multi-axis machining capabilities. A 3-axis CNC machine relies on X-Y-Z axis direction travel to produce basic parts but cannot efficiently handle the complex forms needed for aerospace-quality medical components. Multi-axis machines consist of systems ranging from 4-axis to 9-axis, enabling tools to rotate freely and access the workpiece from every angle.

Aerospace manufacturers need this capability to efficiently machine turbine blades because they have complex airfoil shapes with compound curves. Combining part and tool rotations through a 5-axis CNC machining service enables single-step production of smooth contoured surfaces. Medical applications employ 5-axis machining to make orthopedic implants that precisely match bone structure for accurate patient implantations.

Multi-axis machining achieves accuracy and rapid production while minimizing error because it eliminates the requirement for multiple setups, thus becoming a vital approach for complex shapes.

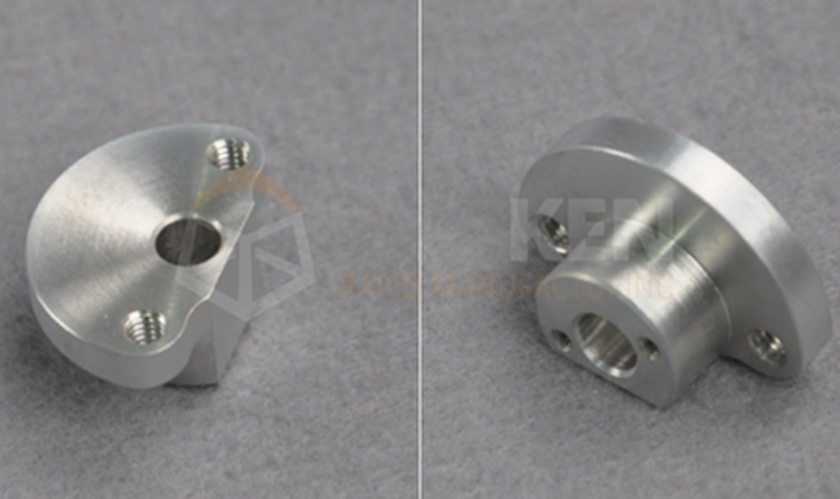

The high complexity of particular designs requires specific cutting methodologies and custom tooling, which CNC machining services provide to maintain precision and surface quality. Engine casings in aerospace operations need specialized treatment because their deep pockets and thin walls produce vibration issues. The medical field requires surgical instruments with strict accuracy control at microscopic dimensions.

The combination of ball-end mills with tapered cutters and micro-tools allows CNC machining to handle complex tight spaces and intricate contours. The ball-end mill produces smooth curved shapes on aerospace structural components and the micro-tool with a 0.1 mm diameter machines exact medical device features like dental drills.

A CNC machining service implements trochoidal milling as an adaptive cutting technique to protect tools and control elevated temperatures that occur during the processing of aerospace and medical materials, including titanium and Inconel.

Complex geometries get machined with high precision through modern tooling methods and advanced cutting techniques that reduce defect possibilities.

The materials used in aerospace and medical parts—such as titanium, stainless steel, and PEEK (Polyetheretherketone)—present unique machining challenges due to their hardness, toughness, or thermal properties. For example, titanium generates significant thermal energy, resulting in deteriorated tools and deformed parts due to thermal effects.

The CNC machining service solves these problems by using high-pressure coolant systems to cool and lubricate the cutting zone to maintain process stability.

PEEK material commonly employed for spinal implant applications in the medical field demands precise control of cutting speeds because excessive operation can lead to melting and surface deterioration. CNC machining maintains precise, complex part production regardless of material limitations through correct adjustment of spindle speed combined with feed rate and depth of cut parameters.

Precise components in aerospace and medical fields must achieve measurements within a range of ±0.005 mm due to their essential applications. The CNC machining service reaches this precision through consistent quality control verification and sophisticated metrological techniques. The machine's programmed design is verified by in-process monitoring systems, especially toolpath verification software, to ensure proper execution of complex geometries during machining operations.

A compressor disc component in aerospace demands the machining of precise cooling channels because their performance depends heavily on accurate dimensions. A medical part, including hip implants, requires perfect contouring of its surface to guarantee the correct fit for the patient's anatomy.

After completing the process, the CNC machining service utilizes coordinate measuring machines (CMMs) together with laser scanning to confirm all features within their required tolerance limits. Thorough quality control, together with precision machining, allows complex geometries to reach consistent results which satisfy aerospace and medical industry standards.

A CNC machining service excels at processing complex geometries because it helps shorten production durations without affecting the final product quality. Engineers can use computer-aided manufacturing (CAM) software to simulate machining processes in advance, which allows them to detect potential conflicts between tools and identify inefficient tool paths. The planning process proves necessary for intricate parts to cut down error frequency and prevent additional work.

When used on aerospace components for landing gear systems a single part needs various machining steps that combine milling together with drilling and turning processes. CNC machining service operations become more efficient and lead times reduce when a service uses single multi-axis setups and optimized toolpaths.

CNC machining enables medical equipment production companies to rapidly shift between different part designs and maintain high precision in their operations of small production runs. The optimized CNC machining process establishes the technology as optimal for manufacturing sophisticated shapes in these two sectors.

CNC machining offers unmatched abilities to manage aerospace and medical applications because of its superior technology and process monitoring capabilities when producing complex shapes. A CNC machining service enables production of complex components through multi-axis machining together with specialized tooling and material-specific strategies and precision quality control and process optimization methods. Manufactured parts fulfill their stringent specific industrial standards because these capabilities operate on items ranging from turbine blades to surgical implants.

Aerospace and medical technologies spread across industries, yet the need for sophisticated, precise components keeps growing due to persistent advancements in their fields. CNC machining service delivers the flexibility combined with precision and efficiency that manufacturers require to tackle future industry challenges, thus making it their essential production tool. The aerospace and medical industries will achieve continuous innovation through complete CNC machining utilization to manufacture parts that expand performance and reliability limits.