Most Innovative Companies to Watch 2026

CIO Bulletin

Warehousing is complex. Labor is expensive. It’s the largest operational expense and the hardest to control. And the biggest gap in all of it is the one thing most operations still don’t have: a system that tells them exactly how many people they need to get today’s work done, and where they should be.

Despite all the technology on the warehouse floor, most teams are still forced to rely on guesswork, tribal knowledge, and yesterday’s activity data to plan the most important part of the operation. And the results are as familiar as they are costly:

LaborAI was built to eliminate this guesswork.

LaborAI is a low-cost, SaaS labor planning platform, developed by operators with more than 50 years of real-world logistics experience, that gives warehouses the accurate, touch-level labor forecasts they’ve always needed but never had. It shows leaders exactly how many people they need, where to deploy them, and what it will take to run the day efficiently and economically. And it’s fast and frictionless. LaborAI deploys in days, requires no IT lift, and delivers a 100:1 ROI for most customers by optimizing the single biggest cost center they have: labor. Since its launch in January 2024, LaborAI has helped customers save more than $25 million in labor costs by exposing hidden inefficiencies and showing organizations precisely where labor is being misallocated - and how to fix it fast.

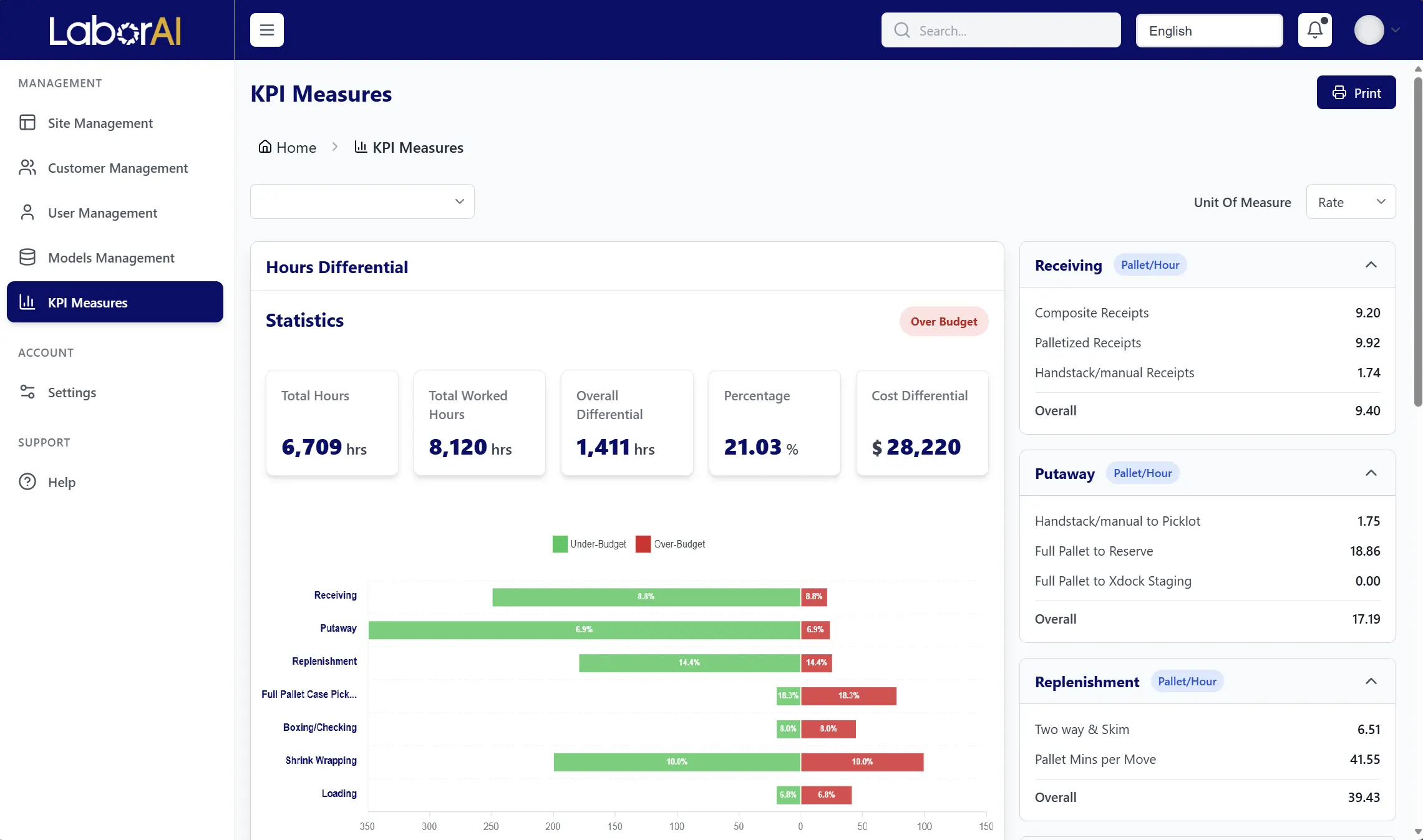

Analyzing 37 critical warehouse touchpoints, LaborAI delivers clear, actionable insights with no complex integrations, no long implementations, and no need for expensive consultants. Managers get the visibility they’ve never had before, leading to fairer schedules, reduced overtime, greater productivity, and stronger retention.

Guided by Founder and CEO Lee Rector, LaborAI brings expert-level intelligence to the warehouse floor, giving teams the confidence to plan proactively instead of reacting shift by shift.

We at CIO Bulletin sat down with Lee to discuss LaborAI’s rapid rise, the problem it solves, and how AI-powered labor planning is reshaping the future of warehouse operations.

Interview Highlights

Could you walk us through the journey of LaborAI, and what problem you were trying to solve?

In warehousing and manufacturing, labor planning remains one of the least optimized components of operations. More than 99% of companies still lack tools to accurately plan labor needs ahead of the work, which leads to reactive staffing, inflated costs, and missed productivity goals.

Even companies attempting a more data-driven approach often rely on basic tools like Excel—useful for rough averages, but nowhere near the precision needed today. Traditional systems fall short:

The real problem is the labor planning gap: determining, in advance, exactly how many people are needed in each department based on incoming and outgoing orders and SKU attributes.

LaborAI was built to close that gap. It is the only SaaS platform that accurately forecasts labor at the operational touch level before work begins, giving leaders the visibility to staff proactively instead of reactively.

What products and services does LaborAI offer—and what makes them different?

LaborAI is the first labor planning platform powered by generative AI and built on a deep database of industrial averaged standards. Unlike legacy systems that require expensive modeling or long implementations, LaborAI instantly calculates labor needs using five core categories:

Users simply upload their order files, and the system profiles labor demand by the hour, day, week, month, or year. LaborAI breaks workloads into 37 operational touchpoints and converts them into clear forecasts for rates, hours, headcount, and cost.

This level of detail and speed gives operators a new level of control - allocating labor proactively and eliminating unnecessary costs before they occur.

How does LaborAI stay aligned with the rapidly changing realities of warehouse operations?

No two days in a warehouse look the same, and LaborAI is designed for that. The platform uses AI to continuously profile real-time workloads before execution, adjusting for SKU mix, fatigue factors, equipment differences, and environmental conditions. This creates a living, dynamic forecast that mirrors actual operations with exceptional accuracy.

How does LaborAI deliver accuracy beyond traditional models?

Where most tools analyze what already happened, LaborAI forecasts what’s about to happen. Its AI-driven engine uses industrial benchmarks and operational descriptors to generate forward-looking labor plans that reflect on-the-ground realities - not historical averages. The result is a clear and highly reliable picture of labor needs before the shift begins.

How does LaborAI support multi-site enterprises, 3PLs, and large warehouse networks?

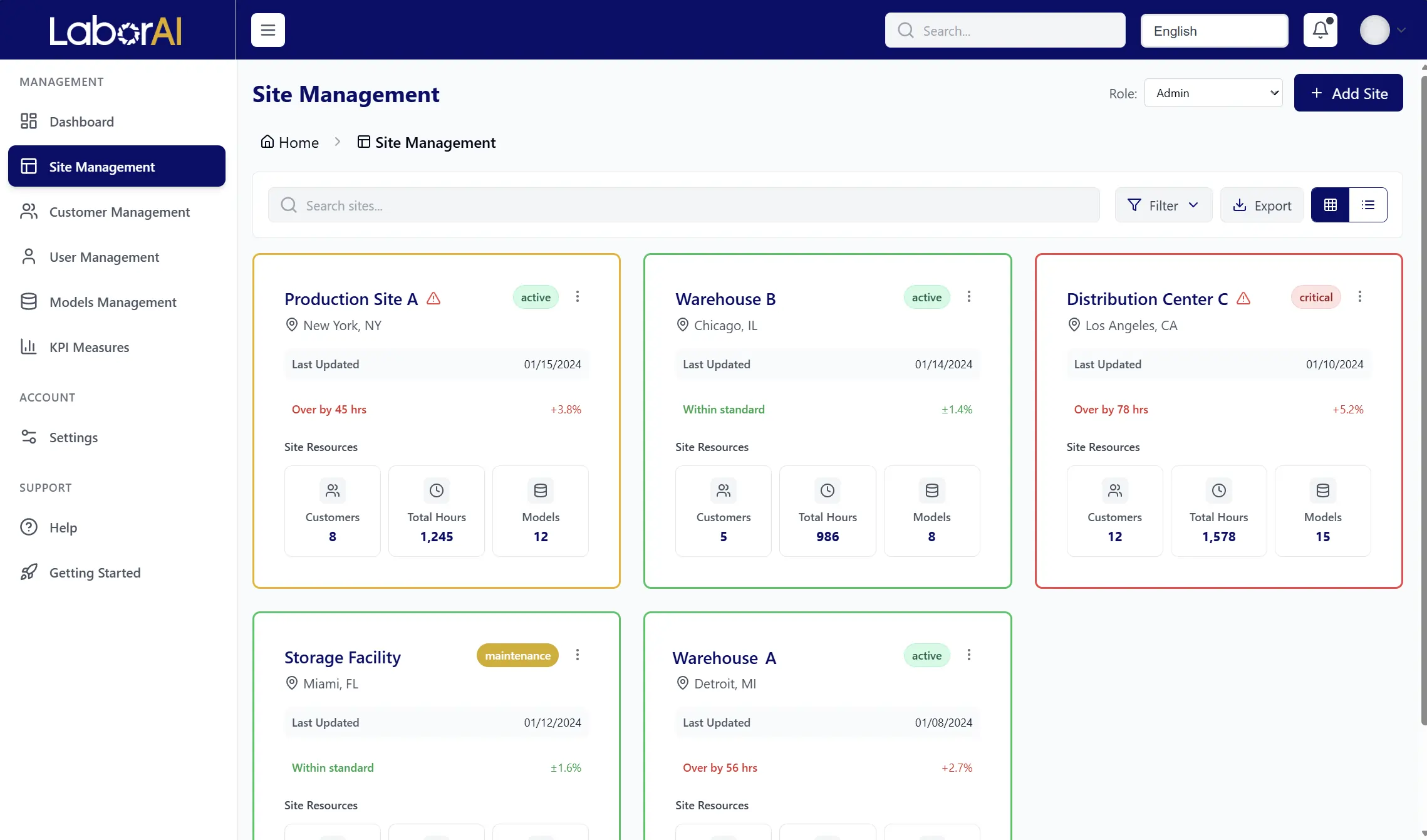

LaborAI is intentionally simple to deploy. Most clients are fully operational within a week, entering their own data and gaining immediate visibility into labor gaps. The interface offers instant clarity, making it easy for leaders across multiple sites to maintain consistency, control, and accountability - without complicated integrations or long onboarding cycles.

Your platform delivers enterprise-grade modeling without heavy integrations. What impact has that had on adoption?

The combination of speed, affordability, and high accuracy has been game-changing. Companies using LaborAI have seen labor cost reductions of up to 25%, dramatic improvements in throughput, and more balanced workloads across teams. Many have realized ROIs of 100:1, proving that precise forecasting is not just operationally beneficial—it’s a major driver of profitability.

With more than 100 warehouses worldwide now using LaborAI, the platform is emerging as a global standard for modern labor planning.

Your proprietary database of 1,000+ Industrial Averaged Standards is a major differentiator. How does it enhance accuracy and reliability?

Our database of over 1,000 Industrial Averaged Standards is foundational to LaborAI’s precision. While other tools depend on historical performance - what the team did - our standards reveal what the team should have done based on validated labor expectations across more than 37 warehouse touchpoints.

This gives planning teams:

Because the standards are universal and benchmarked across industries, they deliver a level of reliability that spreadsheets and legacy systems simply cannot match. LaborAI models are accurate, repeatable, and grounded in fact - not guesswork.

Lee Rector | Founder & CEO

Lee has spent thousands of hours in warehouses, building technology and serving as an executive in the warehousing and logistics space, bringing a unique combination of practical know-how and executive vision. For the better part of a decade, Lee was known as the global firefighter for 3PLs, helping brands such as DHL and DSV run more efficient warehouse operations. Lee was a founder of the North American team at Mantis, a Gartner Magic Quadrant WMS global company, after his own slotting technology company was acquired, and has developed deep domain expertise in how to build and apply technology to support warehouse operations.

LaborAI is the latest example of Lee’s acumen and deep understanding of the market. He was able to identify a massive problem in the industry that no one had solved: there were plenty of execution-oriented software solutions, but none that enabled operator to accurately plan, model, and optimize warehouse labor before decisions were made. Drawing on decades of firsthand experience, Lee created a platform that brings predictive intelligence and operational clarity to labor planning, helping organizations align staffing, productivity, and cost with real-world operational realities.

Insurance and capital markets